Production of welded pipes and hollow sections

| Technical parameters of the line | |

|---|---|

| Pipes | ø 32 mm – ø 102 mm |

| Sections - square | 20 × 20 mm – 80 × 80 mm |

| Sections - rectangular | 40 × 20 mm – 100 × 60 mm |

| Wall thickness | 1.5 mm – 4.0 mm |

| Production lengths | 4200 mm – 12,000 mm |

| Material characteristics | |

|---|---|

| Ultimate tensile strength Rm | Max. 560 MPa |

| Upper yield point Re | Max. 430 MPa |

| Ductility A | Min. 20 % |

Current assortment of pipes and sections

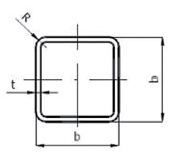

Hollow section with square cross-section per ČSN EN 10219-1 and ČSN EN 10219-2

| Dimensions | t | |||||

|---|---|---|---|---|---|---|

| b × b | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

| 20 x 20 | x | x | ||||

| 25 × 25 | × | × | × | |||

| 30 × 30 | × | × | × | × | ||

| 35 × 35 | × | × | × | × | ||

| 40 × 40 | × | × | × | × | × | × |

| 45 × 45 | × | × | × | × | × | |

| 50 × 50 | × | × | × | × | × | |

| 60 × 60 | × | × | × | × | ||

| 70 × 70 | × | × | × | × | ||

| 80 × 80 | × | × | × | × | ||

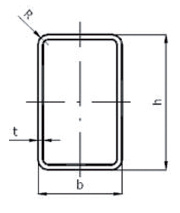

Hollow section with rectangular cross-section per ČSN EN 10219-1 and ČSN EN 10219-2

| Dimensions | t | |||||

|---|---|---|---|---|---|---|

| h × b | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

| 40 × 20 | × | × | × | × | ||

| 40 × 30 | × | × | × | × | ||

| 50 × 30 | × | × | × | × | × | × |

| 60 × 30 | × | × | × | × | × | |

| 50 × 40 | × | × | × | × | × | |

| 60 × 40 | × | × | × | × | × | |

| 80 × 40 | × | × | × | × | ||

| 80 × 60 | × | × | × | × | ||

| 100 × 60 | × | × | × | × | ||

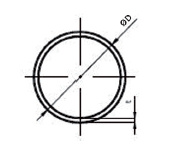

Hollow section with circular cross-section per ČSN EN 10219-1 and ČSN EN 10219-2

| Dimensions | t | |||||

|---|---|---|---|---|---|---|

| ø D | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

| 33.7 | × | × | × | × | ||

| 42.4 | × | × | × | × | × | |

| 48.3 | × | × | × | × | × | |

| 57 | × | × | × | × | × | × |

| 60.3 | × | × | × | × | × | × |

| 76 | × | × | × | × | ||

| 89 | × | × | × | × | ||

| 101.8 | × | × | × | × | ||

Other grades of steel, dimensions, tolerances, and other production or packaging specifications are subject to negotiation prior to signature of the purchase agreement.

General technical information

Material: pipes and sections are cold shaped from easily weldable alloy and fine-grain structural steel suitable for hot dip galvanizing.

Surface: the condition of pipe and section materials is after hot rolling and cold processing.

Surface protection: pipe and section surfaces are protected from corrosion due to humidity with an oil emulsion after cold shaping.

Quality check:the production process always includes pre- and post-production quality checks. The pre-production check includes a weight check, a dimension check, a visual inspection of the surface of the source material, and a check that the accompanying documentation is complete. The post-production check includes a dimension check, including shape and straightness, weight, packaging, and labelling. Welds are tested using an expansion test. Tensile test per ČSN EN ISO 6892-1. Declaration of performance (for download), Certificate of conformity of the factory production control (for download).

Packaging: SSC Ostrava has a standard packaging method that ensures sufficient protection during handling and shipping (strapping and clips). Pipes and sections are bound with steel strapping into 1000-2000 kg bundles.

Testing and inspection documents: we issue product certification 2.2 per ČSN EN 10204.

| File description | Size | File for download |

|---|---|---|

| Declaration of Performance | 415.5 KB | |

| Certificate of conformity of the factory production control | 505.69 KB | |

| Certificate EN ISO 9001:2015 SSC OV | 384.67 KB |