Tests

Information on the Ferona test lab, Steel Service Centre

The laboratory is a member of the Association of Czech Test Facilities and Laboratories, and is authorized to use the association's stamp. Based on inter-laboratory comparison of the results of spectral analyses, the laboratory has received a Certificate of Competence.

It is also certified according to EN ISO 9001:2015

Lab equipment:

a) LabTest 4.100.SP1, supplied by LaborTech Opava

The LabTest 4.100.SP1 is a universal 4th-generation testing machine for both static and dynamic tension, compression, and bend testing. It complies with ČSN EN ISO 7500-1, ČSN EN ISO 6892-1, and other international standards for test machines. Its 100 kN rated loading makes it possible to test all metallurgical products sold by Ferona, a.s.

The LabTest 4.100.SP1 is a universal 4th-generation testing machine for both static and dynamic tension, compression, and bend testing. It complies with ČSN EN ISO 7500-1, ČSN EN ISO 6892-1, and other international standards for test machines. Its 100 kN rated loading makes it possible to test all metallurgical products sold by Ferona, a.s.

its software includes data transmission, machine control, graphic recording during testing, a table of measured values, and static calculation. The SW also makes it possible to produce a test report that includes the measured data including chemical analysis and measured hardness of material.

Sample requirements:

Flat samples up to 6 mm thick, a strip with minimum dimensions 25 x 300 mm

Rods and sections, min. length 300 mm.

b) HPO 250 durometer, supplied by LaborTech Opava

The HPO 250 durometer measures material hardness using the Brinell and Vickers. The test is evaluated using the focusing screen of the maesuring device. The instrument is regularly calibrated to nominal loads of 98, 07 N, 612, 9 N and 1839 N.

The HPO 250 durometer measures material hardness using the Brinell and Vickers. The test is evaluated using the focusing screen of the maesuring device. The instrument is regularly calibrated to nominal loads of 98, 07 N, 612, 9 N and 1839 N.

Sample requirements:

A material sample on which an area of at least 20 mm in diameter can be ground down.

c) SPECTROMAXx M6 from Spectro

The PECTROMAXx M6 is a fixed device that performs non-destructive chemical analysis of basic materials: Al, Cu, Fe, Mg, and their alloys.

The PECTROMAXx M6 is a fixed device that performs non-destructive chemical analysis of basic materials: Al, Cu, Fe, Mg, and their alloys.

Analyzed elements

C, Mn, Si, P, S, Cr, Mo, Ni, Al, Zn, Mg, Co, Cu, Nb, Ti, W, Pb, Sn, As, Zr, B, Fe, N.

Sample requirements:

A material sample on which an area of at least 15 mm in diameter can be ground down. For example sheet metal measuring at least 50 x 50 mm, a rod at least 40 mm in length, etc.

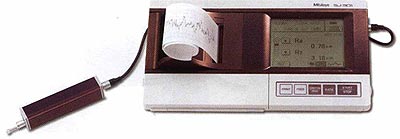

d) A Mitutoyo SJ-301 surface roughness measuring instrument

The Mitutoyo SJ-301 is a portable surface roughness measuring instrument that can measure surface structure and characterize it using a number of parameters according to various domestic and international standards. Measurement results are displayed digitally and in graphic form, and can be printed on a built-in roll printer.

The Mitutoyo SJ-301 is a portable surface roughness measuring instrument that can measure surface structure and characterize it using a number of parameters according to various domestic and international standards. Measurement results are displayed digitally and in graphic form, and can be printed on a built-in roll printer.

Measurement range: 300 μm (±150 μm) or 12 000 μin (±6000 μin).

e) A metallographic microscope for examining the surface of metal materials

The MTM 400 metallographic microscope can be used to examine the crystalline structure or microscopic surface defects of materials. The instrument is equipped with a set of interchangeable lenses (PL4/0.10, 10x/0.25, 20x/0.40, 40x/0.65) and a camera that transmits the image to a PC, where it can be stored, printed, or edited and saved in JPG format.

The MTM 400 metallographic microscope can be used to examine the crystalline structure or microscopic surface defects of materials. The instrument is equipped with a set of interchangeable lenses (PL4/0.10, 10x/0.25, 20x/0.40, 40x/0.65) and a camera that transmits the image to a PC, where it can be stored, printed, or edited and saved in JPG format.

f) DUALSCOPE MP20 coating thickness gauge

This instrument uses either magnetic induction (to for example measure zinc, tin, chrome, copper, paint, and plastic layers on steel or iron) or eddy currents (to for example measure elox, paint, varnish, and plastic layers on aluminium, copper, and other non-ferrous metals).

This instrument uses either magnetic induction (to for example measure zinc, tin, chrome, copper, paint, and plastic layers on steel or iron) or eddy currents (to for example measure elox, paint, varnish, and plastic layers on aluminium, copper, and other non-ferrous metals).

Measurement range:

0 – 1500 μm – magnetic induction

0 – 1200 μm – eddy currents.

Sample delivery:

Test samples must be indelibly marked so they can be uniquely associated with information provided in an order or list.

The order or list must specify the following:

- a description of the sample;

- the brand of material (if known);

- the number of samples;

- sample orientation with respect to rolling direction (if known);

- identification mark (sample identification);

- type of test(s) required (tensile, chemistry, hardness).